Characteristics

Excellent fluidity of the mixture, easy for manual or mechanical sand filling, good roughness of casting surface and high dimensional accuracy.

Rapid curing speed, no water generated during reaction, curing homogeneously with excellent thorough-hardening.

Sand core (mold) is with good collapsibility and easy to reclaim, reduce crack defects and consumption of original sand.

High productivity, suitable for steel, iron and nonferrous castings, have excellent quality records on these castings.

Free of Sulfur, Phosphorus, no resulfurization and phosphorization generated

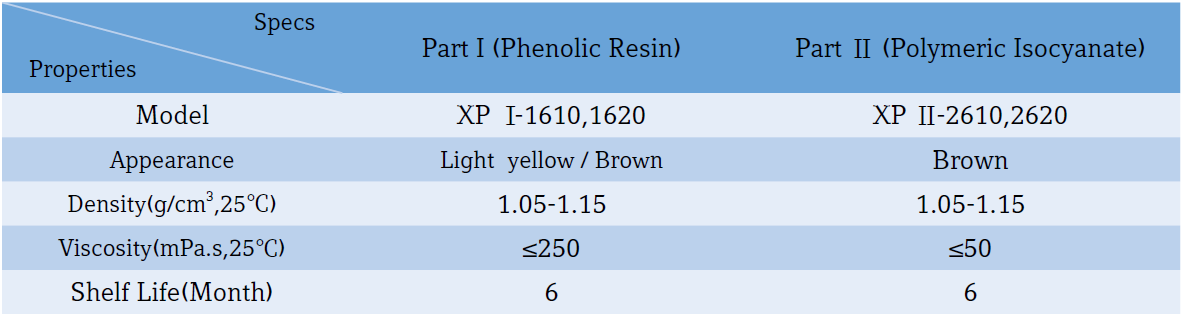

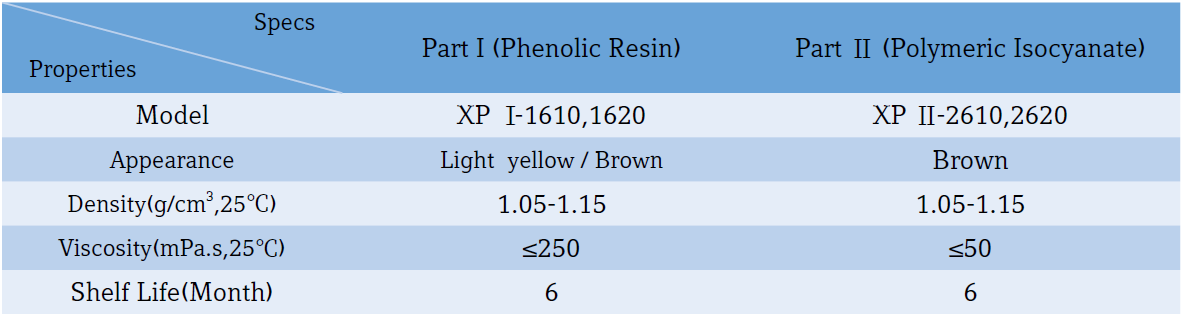

Specifications / Models

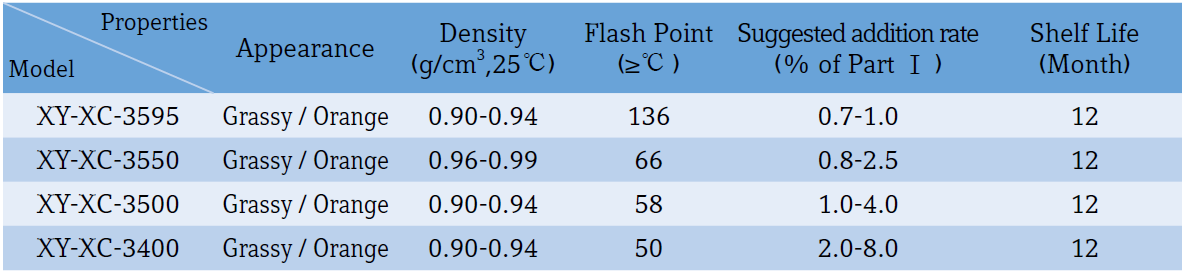

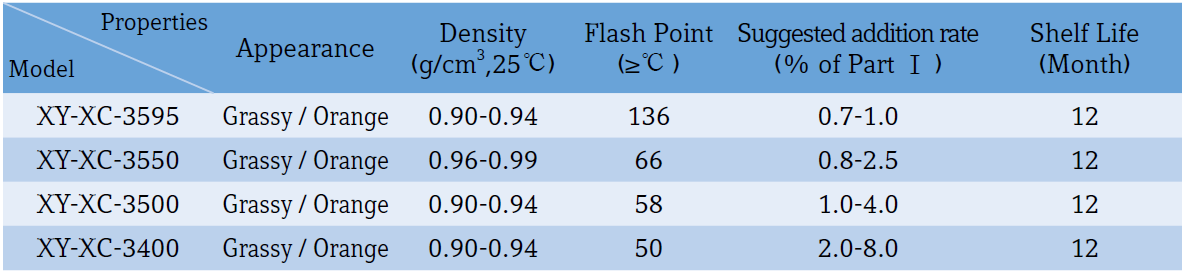

XY-XC Curing Agent

How to use

Ratio: original sand (reclaimed sand): (Part I resin: catalyst): Part II resin=100: <(0.5-1.0): (0.6-8% of Part I resin)>: (0.5-1.0). Match with XY-XC series catalyst of Phenolic Urethane (PU) no-bake resin to get high-point.

If use intermittent sand mixer, firstly add catalyst into part I resin and blend with sand for 1.5-2.0 minutes, then add part II resin into the mixture to blend for another 1-2 minutes evenly.

If use continuous sand mixer, firstly blend catalyst with part I resin evenly, then pump Part I and Part II into the sand mixer.

Core making or molding instantly after mixing, in order to get rid of fluidity fail for mixture sticky.

If it's single or small quantity handicraft, we propose mixture concocted as below:

Firstly concoct catalyst with part I resin evenly, and then blend with original sand (reclaimed sand) for 1.5-2 minutes evenly.

Add part II resin into original sand (reclaimed sand) then blend 1-2 minutes evenly.

Bend the two kinds of mixture together when using.

Pay attention when using Phenolic Urethane (PU) no-bake resin:

Use high quality sand, moisture content and clay content ≤0.3%, acid consumption (Ph=3)≤8, grain shape and granularity should meet technical standard.

Part I resin: Part II resin=(50-55%): (50-45%). Prefer more part I resin to get high-point.

Packing and Storage

No-bake Phenolic Urethane Resin is sealed in metal drum with 220kg per tank or IBC tank with 1000kg per tank; Curing Agent is sealed in iron drum with 180kg per drum.

Resin and Curing Agent should be deposited in cool, dry and well-ventilated place, keep away from moisture, fire, heat source and direct sunshine.

Wear labor protection articles, if contact with body incautiously, rinse by clean water instantly, take medical care when necessary.